MIV800 Vertical Shaft Impactor

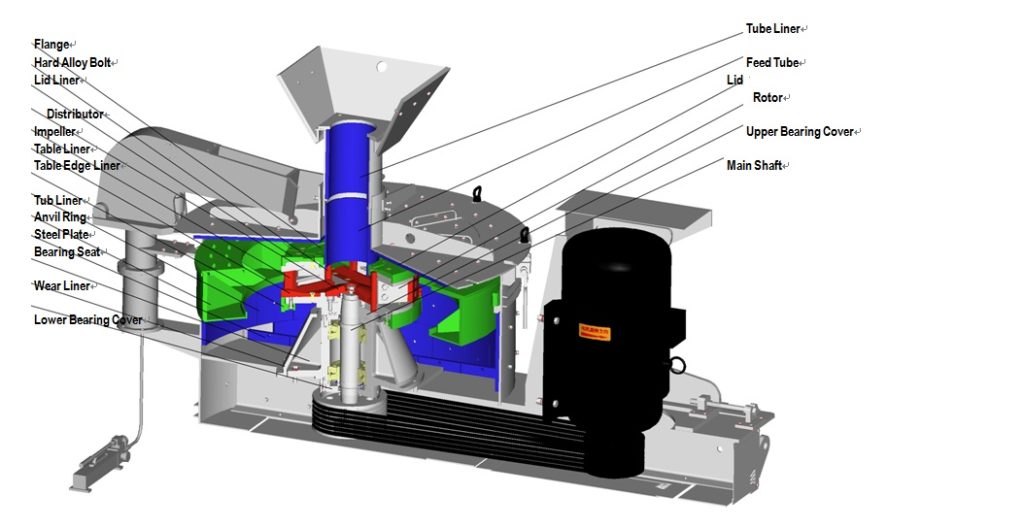

With high speed rotating impellers, the MIV-800 Vertical Shaft Impactor throws material out from center to circumference, by using the material’s own centrifugal force to cause impact with the impeller shoes or the anvil faces, resulting in rock-on-rock or rock-on-iron crushing.

With it's wide operation range and first class performance, it is the most effective and reliable crusher, especially suitable for fine crushing and medium fine crushing of grinding material, fire-resistant material, cement, quartz sand, steel grit, furnace cinder, copper ore, iron ore, gold ore, river gravel, concrete aggregate, asphalt aggregate, and brittle material. This highly effective and energy saving crusher is also a superior and first rate sand production equipment and can save up to 50% of energy compared with traditional sand making machines. According to customer's requirements, MIV-800 can be equipped with closed rotors or open rotors.

Features:

- According to customer’s requirements, MIV-800 can be equipped with closed rotors or open rotors.

- New, special, and simple structure for smooth operation, low operating cost.

- Quick exchange between “rock-on-rock” and “rock-on-iron” applications, only one machine for crushing and sand production. “Rock-on-rock” technology reduces parts wear and production cost.

- Low energy consumption, high production, high crushing ratio, energy saving.

- Re-shaping function, product shows cubical form, high bulk density.

- During production, stone material forms a protective layer, which protects the machine from wear and enhances durability.

- Few abrasive parts are made of specially hard wearing resistant material, for small volume, low weight, and convenience during exchange.

- The automatic air circulation system reduces dust and powder.

- Little influence of material’s moisture content, which can reach up to 8%.

- A lubrication oil station with an oil pump for circulatory lubrication of the main shaft bearing ensures constant oil supply to the main machine, as well as automatic control and accident alert.

- The upper lid can be lifted using a hydraulic system; easy operation.

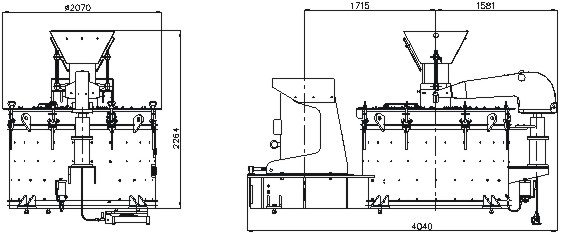

| Max Feed Size (in/mm) | Rotor Diameter (in/mm) | Rotor Rotation Speed (rpm) | Capacity | Electric Power (HP/kw) | Weight w/o Motor (lbs/kg) |

|---|---|---|---|---|---|

| 2in / 50mm | 32in / 800mm | 1200-1800 | 35-170 TPH | 270 / 200 | 16,940 / 7,700 |

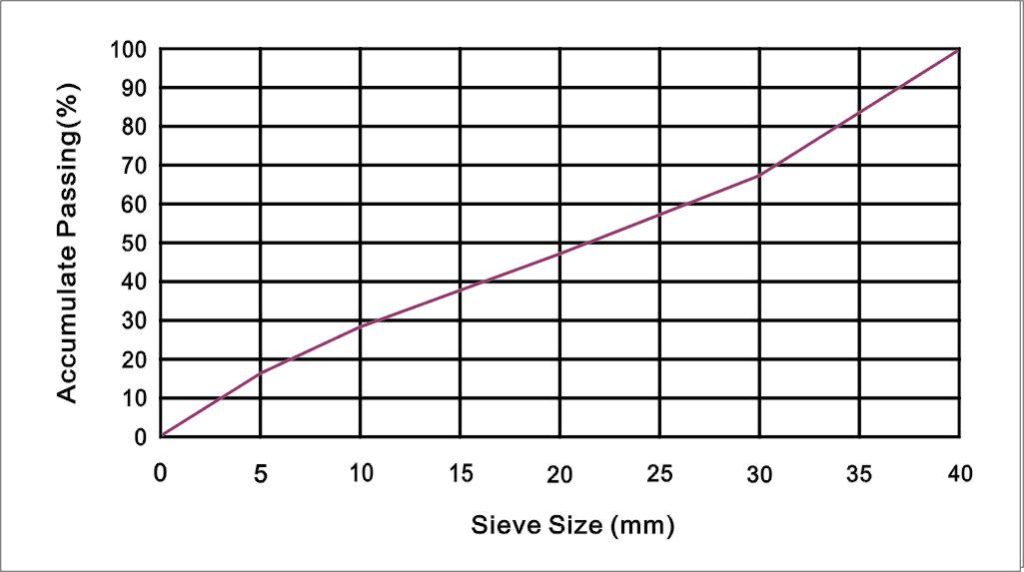

Note: The processing capacity mentioned above is the gross production in open circuit. Production capacity is related with operating conditions such as physical properties of the crushed material, max. feed size, plant configuration etc.

Capacity based on continuous regulated feed of clean, dry limestone of normal hardness with a bulk density of 1.6 ton/m3. Capacity may vary +/- 25% with the size and nature of the rock and the working conditions of the plant. All parameters are for reference only & subject to change without notice.

Have questions about what we do? Interested in our product or becoming a partner? The first step is to get in touch with us. Head to our Contact Page and connect with the office in your area.